Driving down costs. Speeding up production.

Every food and beverage production needs to accommodate diverse capacity and flexibility requirements. Whether you're entering new product categories, seeking increased flexibility or aiming to ramp up production, our diverse selection of filling machines for aseptic, chilled, and food production provides flexible and cost-effective solutions, ensuring your business remains agile and efficient.

With a comprehensive range of filling machines, we can ensure an efficient running of your production process. We prioritise driving down operation costs and through new innovations, we aim to enhance efficiency, implementing machines that can lower the operational cost.

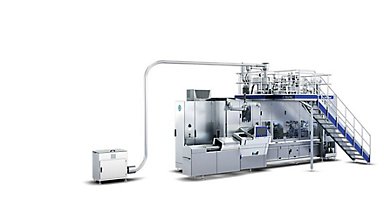

Filling machines

Explore our wide range of filling machines designed to improve food safety and quality, as well as reduce costs.